Cooling solutions for marine and industry

We provide you with outstanding products for cooling main engines, auxiliary engines and generator sets.

Boxcoolers

Using Blokland boxcoolers in the design of efficient cooling system, has been done during many years for different types and sizes of ime vessels and installations. Installed in the primary cooling circuit, boxcoolers obviate the need for raw water pumps, filters and piping systems and prevent the corrosion issues related to them. Over the years different types of workboats, cargo vessels, fishing boats, ferries and dredgers have been using these coolers for main engines, generators and auxiliary systems. Nowadays boxcoolers are not only used in modern fuel-saving and green fuel propulsion solutions, but are also part of the fuel saving measures.

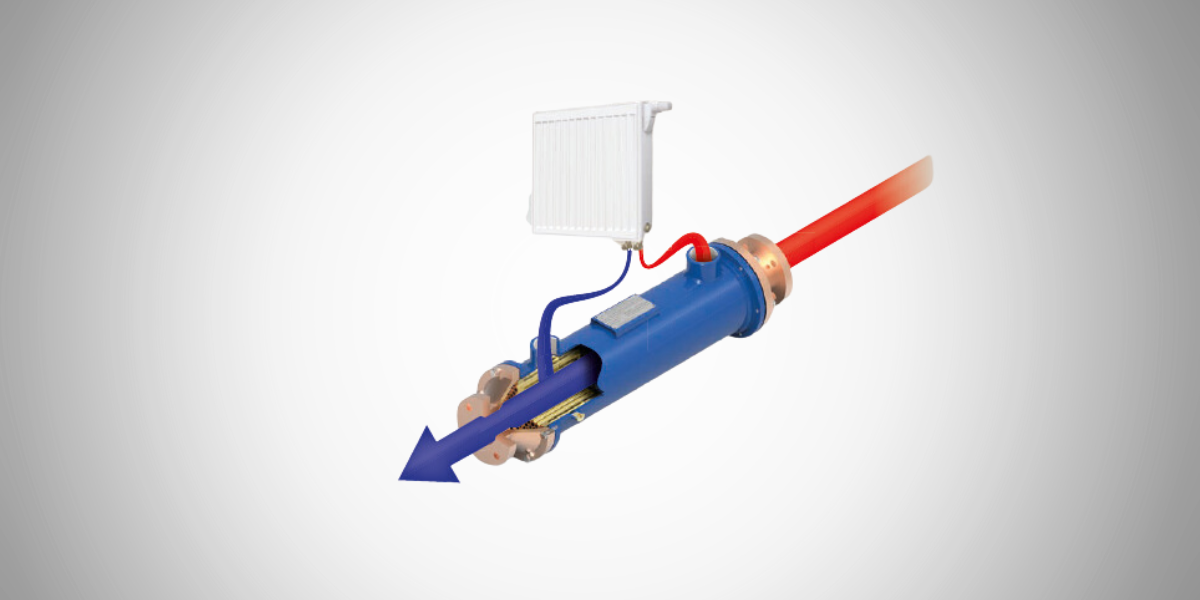

Heat recovery

With these heat exchangers of Blokland Non Ferro you make good use of the waste heat of your engine. The waste heat of approximately 80°C can be used to fully or partially heat your sleep- and living quarters by using a heat exchanger. The installation is simple and the installation costs are low. When the pipework for the central heating system is properly installed and by mounting the heat exchanger vertically, the system works through natural circulation and a pump is not necessary. In short: a product we warmly recommend!

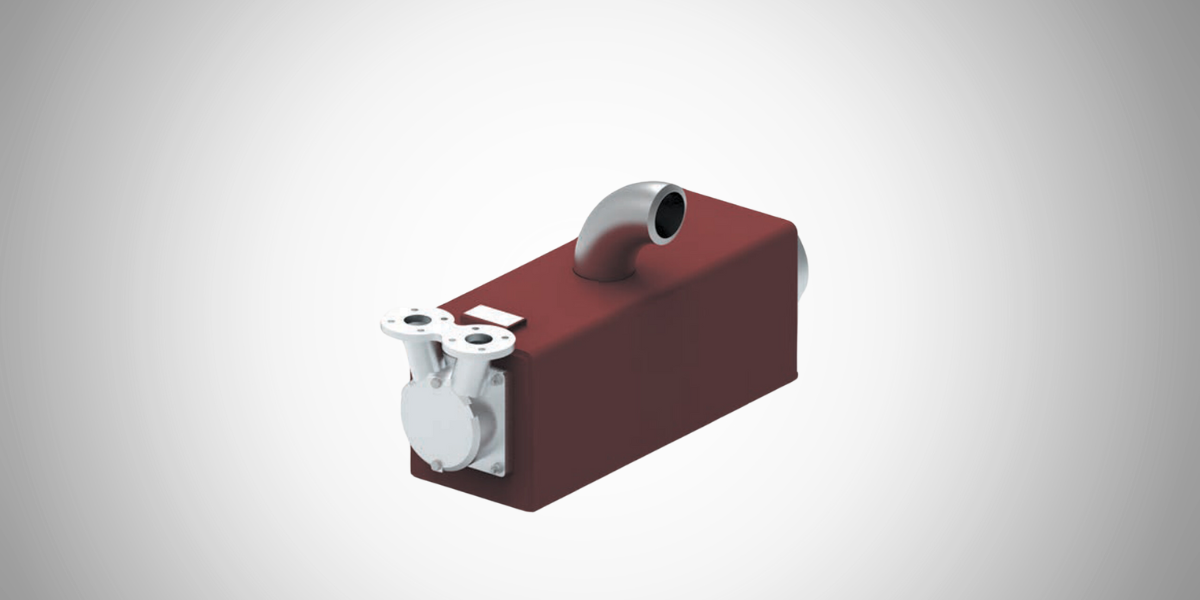

Bottom-type coolers

The bottom-type cooler is an ideal cooling system for pleasure and commercial shipping. The steel box of the bottom-type cooler is placed inside against the bottom of the ship. As a result, the bottom of the ship remains completely smooth. So there are no protruding parts to damage or weed trays to clog. You do not need an extra outboard water pump in this case. Installation is simple and the tube stack can be disassembled. Bottom-type coolers are very suitable for places with a low installation height.

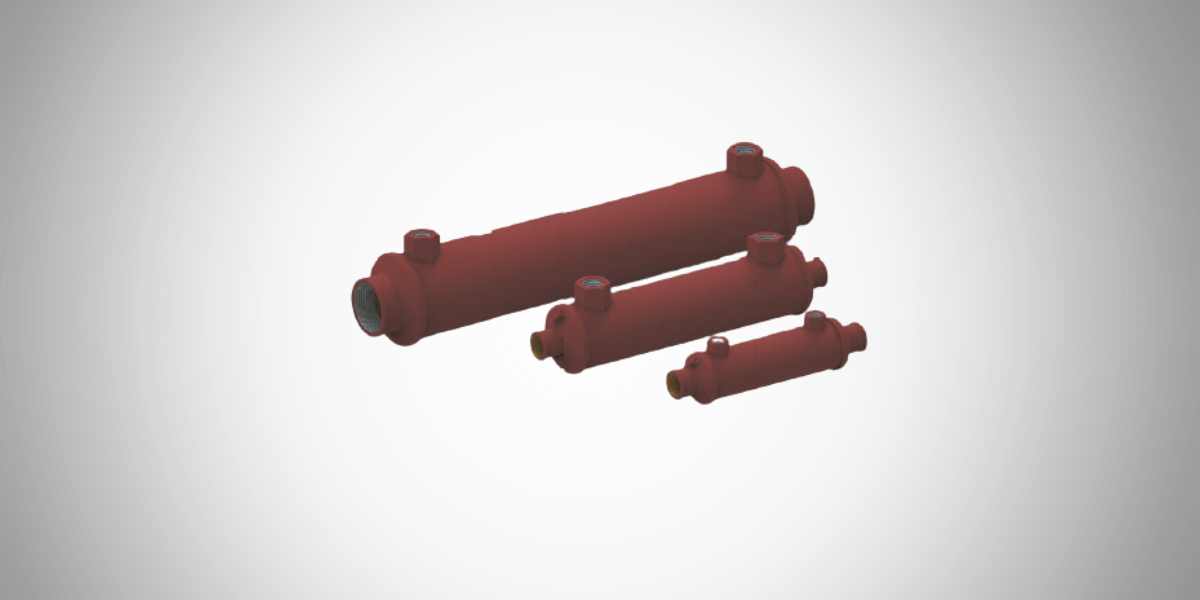

Heat exchangers/oil coolers

The soldered coolers type 55, 75 & 90 are available in single and double circuit versions. The coolers with single circuit can be used as an oil cooler or heat exchanger. The coolers with double circuit are suitable for a combination of engine-oil cooler and gearbox cooler. The end caps are soldered.

Heat exchangers/oil coolers

Blokland is leading in the production and supply of Shell & Tube heat exchangers/oil coolers type 100, 140, 165, 200, 275 and 400. These coolers are suitable for water, water-glycol mixture and various oils. The tube stacks are removable for service and maintenance. Blokland has a wide range of competitively-priced heat exchangers. We have many heat exchangers in stock, which means short lead times.

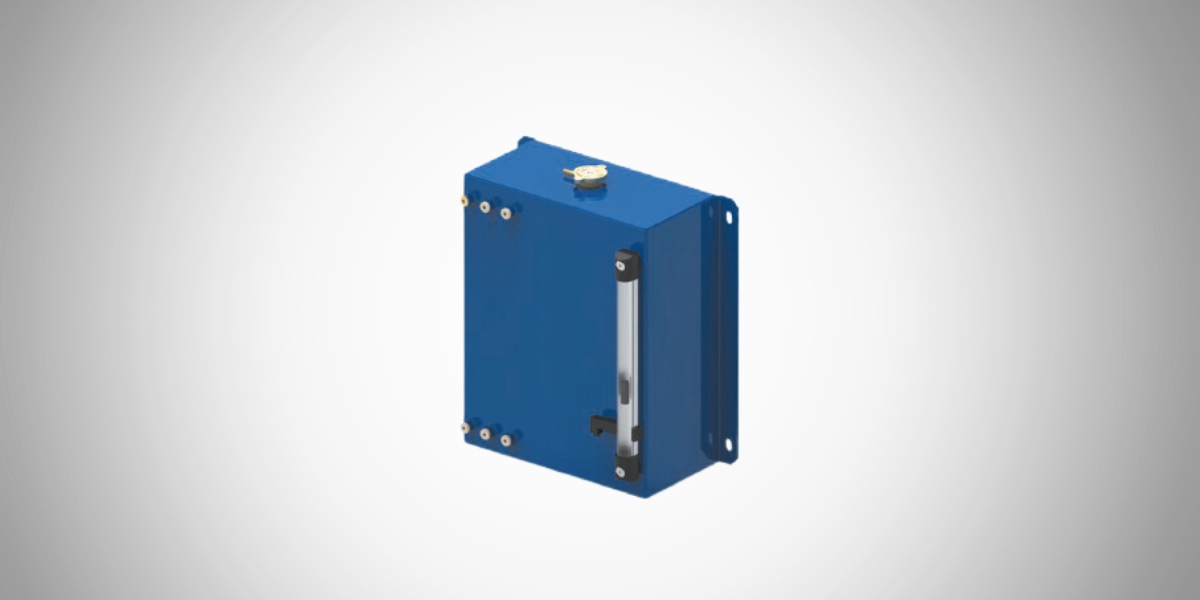

Expansion tanks

Every cooling system is equipped with an expansion tank. Blokland supplies standard expansion tanks with a capacity of 5, 10, 15, 24, 40, 60 and 80 liters from stock. These expansion tanks are equipped with a 1” or 2” BSP thread connection. The expansion tanks are supplied fully assembled with a pressure cap of 0.5 bar. A sight glass and level switch are used to inspect the tank. We are also able to deliver custom-made expansion tanks.

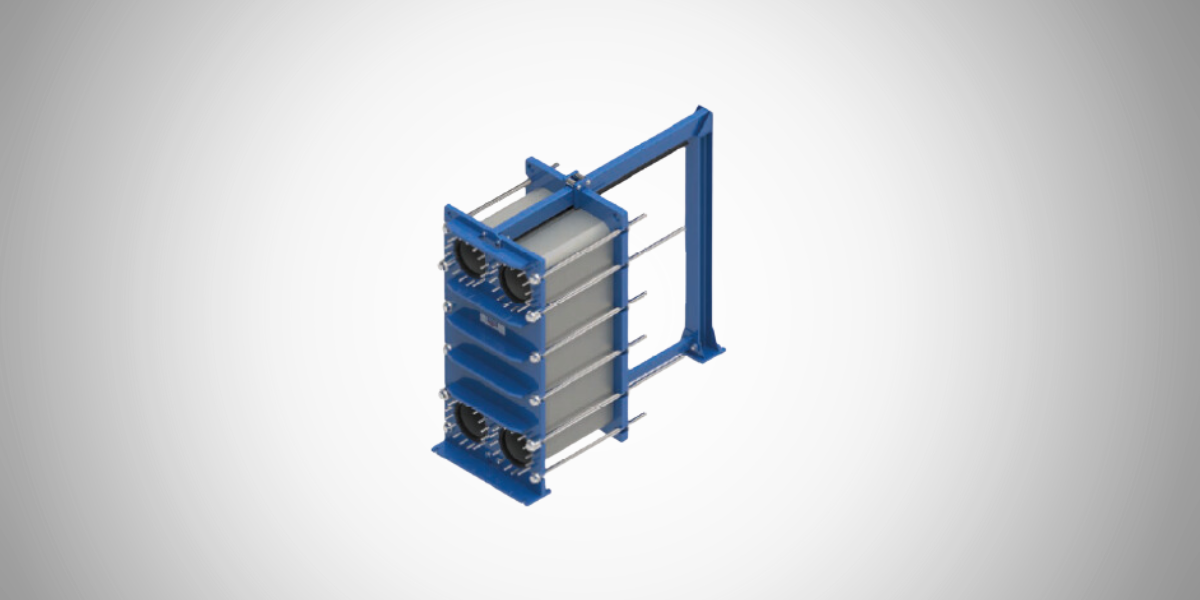

Plate heat exchangers

The plate heat exchangers consists of a pack of heat transfer plates, with port holes, compressed by the frames and tightening bolts. The plates are made of pressed titanium or stainless steel sheet metal with a corrugated pattern. The corrugated plate channel are designed to achieve maximum heat transfer. Each plate is provided with an elastomeric gasket which seals between channel and directs the fluids into alternate channel.

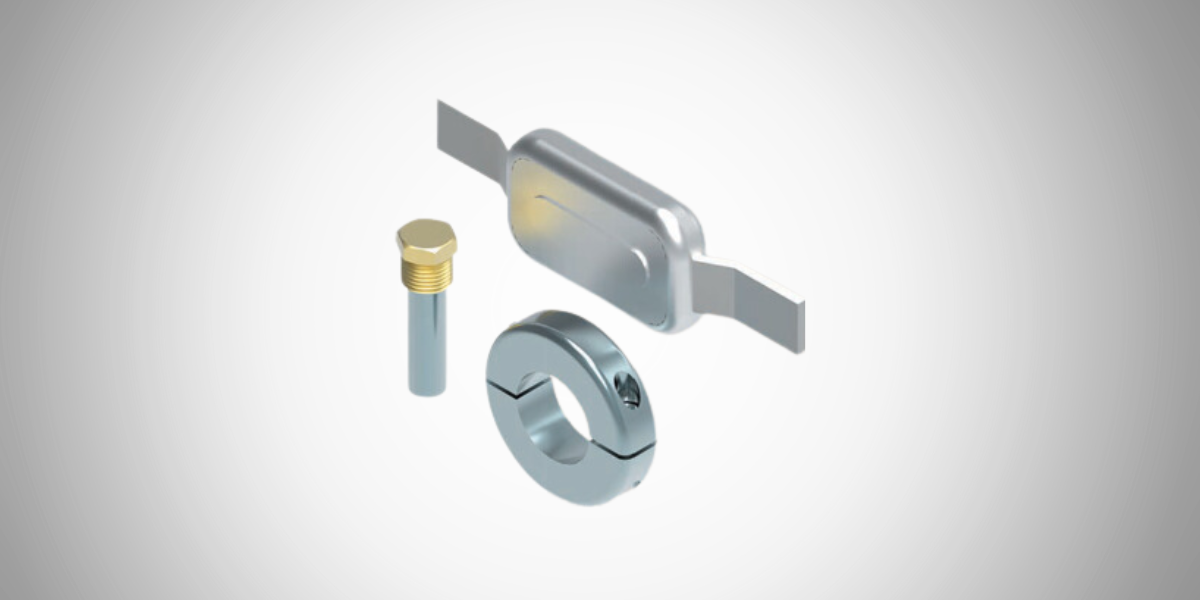

Cathodic protection

In order to protect metal parts under water, cathodic protection by means of anodes is necessary. Blokland offers a broad range of several types of zinc, aluminium and magnesium anodes.